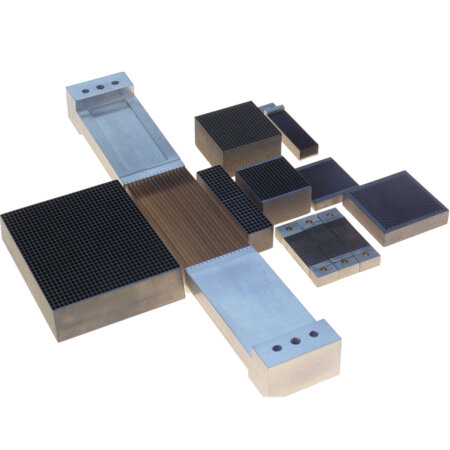

Anti-Scatter Grids for CT Scanners

Nuclear Shields manufactures precision anti-scatter grids for computed tomography detector systems. Our CT grids reject scattered radiation before it reaches the detector array, reducing artifacts and improving image contrast in diagnostic CT, cone-beam CT, and interventional imaging applications.

Scatter rejection for CT imaging

Scattered X-rays degrade CT image quality by adding noise, reducing contrast, and creating characteristic cupping artifacts. Anti-scatter grids positioned in front of the detector array absorb off-axis photons while transmitting primary radiation, significantly improving the signal-to-noise ratio and diagnostic image quality.

Additional information

- Shielding materialLead, Tungsten

Product description

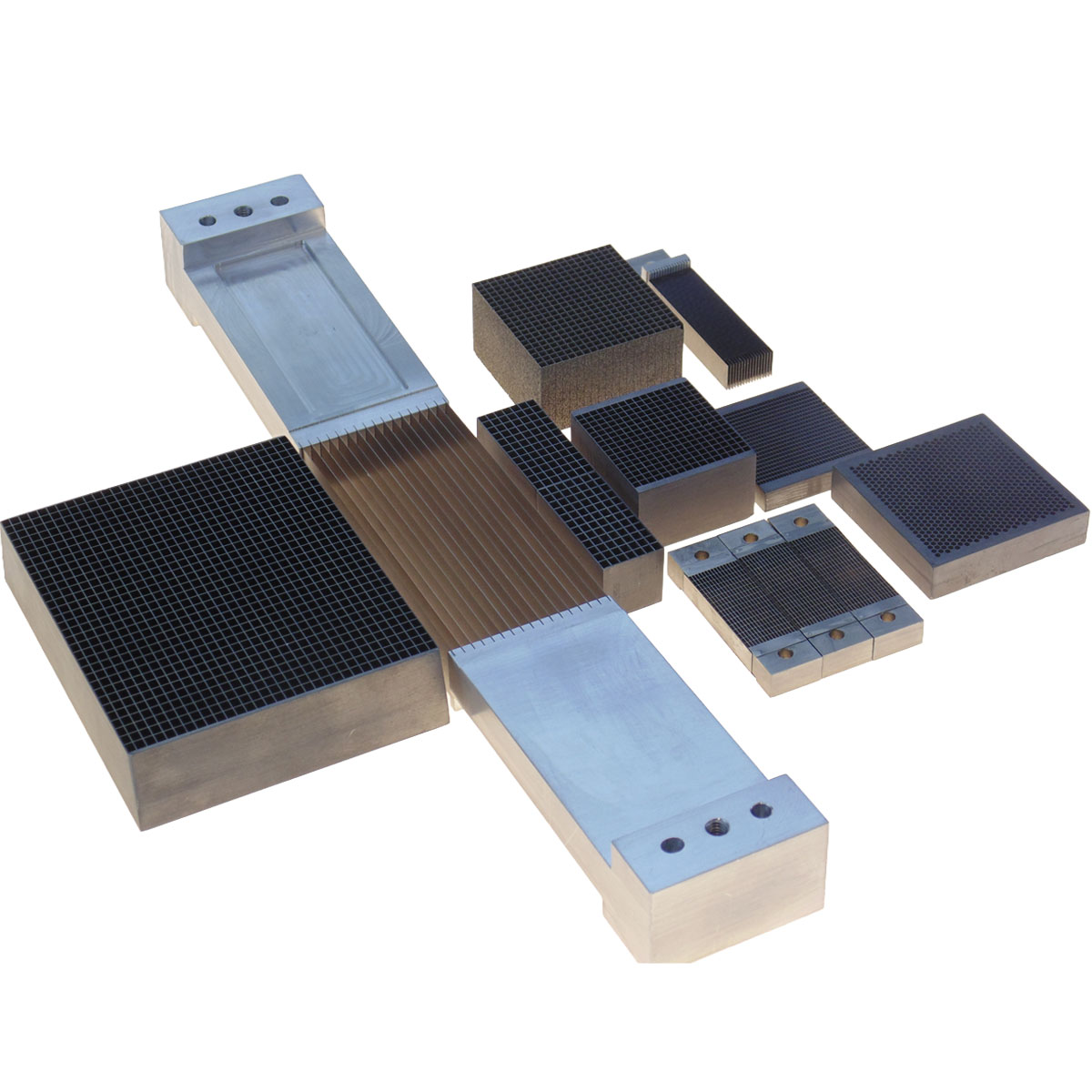

1D and 2D grid configurations

Nuclear Shields offers both one-dimensional and two-dimensional anti-scatter grid designs to match your system geometry and scatter rejection requirements:

1D Anti-Scatter Grids:

Linear septa aligned perpendicular to the scan plane reject scatter in the primary direction. These grids suit conventional multi-slice CT where scatter predominantly originates from within the scan plane. The simpler geometry offers lower manufacturing cost and reduced primary attenuation compared to 2D designs.

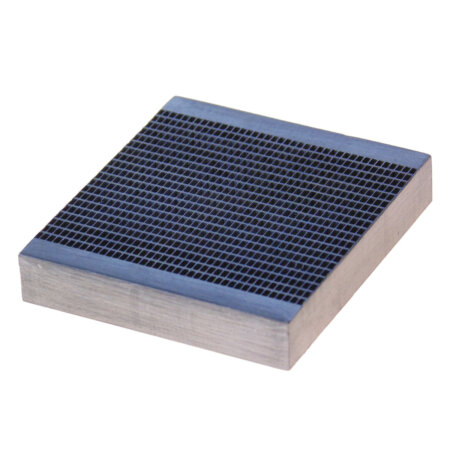

2D Anti-Scatter Grids:

Crossed septa forming a cellular grid pattern reject scatter from all directions. Two-dimensional grids provide superior scatter rejection for cone-beam CT, wide-coverage CT, and other geometries where scatter arrives from multiple angles. The enhanced rejection comes with higher primary attenuation, requiring appropriate technique adjustment.

Material options

We manufacture CT anti-scatter grids in both tungsten and lead, each offering distinct advantages:

Lead grids:

Cost-effective for standard grid ratios – Proven performance in conventional CT applications – Suitable where septa thickness is less constrained – Lower material cost for large-area grids

Tungsten grids:

Higher atomic number (Z=74) provides superior attenuation per unit thickness – Thinner septa enable finer pitch for high-resolution detectors – Better dimensional stability – Preferred for premium CT and compact CBCT systems

Precision manufacturing

CT anti-scatter grids demand exceptional manufacturing precision to avoid introducing artifacts. Nuclear Shields maintains tight tolerances on septa thickness, spacing uniformity, and focal alignment. Our quality processes ensure consistent grid performance across production volumes, supporting OEM manufacturing programs with reliable supply.

Each grid undergoes dimensional verification and visual inspection before shipment. For critical applications, we offer enhanced inspection protocols including X-ray verification of internal geometry.

Detector integration

We work with CT manufacturers to deliver grids optimized for their specific detector geometries:

- Grid pitch matched to detector pixel dimensions

- Focal alignment to source-detector geometry

- Mechanical interfaces for detector module integration

- Curvature for curved detector arrays where required

- Segmented designs for modular detector architectures

Whether you’re developing a new CT platform or need replacement grids for existing systems, Nuclear Shields provides the engineering support to ensure optimal integration.

Contact usProduct attachments

Login to see the attachments, otherwise contact us