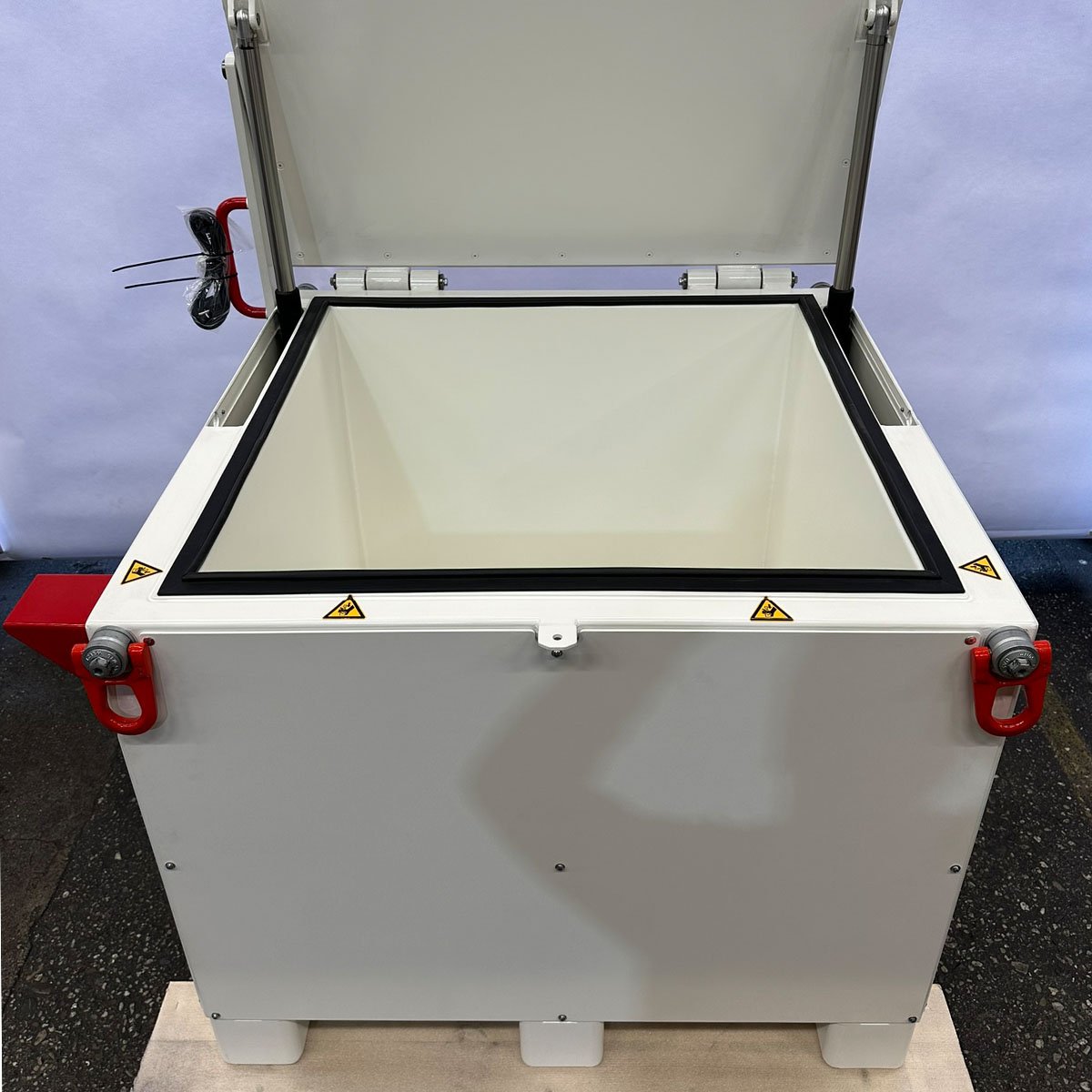

Shielded Decay Cave

The Lead Shielded Decay Cave provides secure, shielded storage for radioactive production waste during decay periods. Featuring an electric actuator system that opens the heavy lead-lined lid at the push of a button, this decay cave enables safe and ergonomic access in high-throughput manufacturing environments. The generous interior cavity accommodates waste containers, processing residues, and contaminated materials from radiopharmaceutical production operations.

Additional information

- Shielding materialLead

- Shielding thickness25 mm

- Outside dimensions1088 x 994 x 892 mm (w x d x h)

- Inside dimensions800 x 748 x 650 mm

Product description

Electric actuator for high-frequency access

Radiopharmaceutical production facilities generate waste continuously throughout manufacturing shifts. The integrated electric actuator system raises and lowers the heavy shielded lid without manual effort, eliminating operator fatigue during frequent access cycles. Operators simply activate the control to raise the lid smoothly and consistently, maintaining safe distance from cavity contents.

An emergency stop button provides immediate halt capability, ensuring operator safety if lid movement needs to be stopped during operation. The actuator system operates on standard facility power with a dedicated power supply unit mounted on the container.

Designed for production environments

Nuclear Shields engineered this decay cave for facilities that manage continuous waste streams from radioisotope and radiopharmaceutical manufacturing. The shielded enclosure reduces dose rates in adjacent production areas while materials undergo natural radioactive decay to levels suitable for conventional disposal or further processing.

The rectangular interior cavity measures 800 × 748 × 650 mm (L × W × H), providing ample volume for:

- Production waste from radioisotope manufacturing

- Hot cell operational waste and contaminated consumables

- Failed batches and quality control samples

- Processing residues from generator manufacturing

- Contaminated tools and materials from shielded enclosures

25mm lead shielding

The decay cave provides 25 mm of lead shielding on all sides—walls, lid, and base. This shielding thickness delivers effective dose rate reduction for typical short-lived isotopes used in nuclear medicine and research applications, including Tc-99m, I-131, F-18, and similar radionuclides commonly managed through decay-in-storage programs.

Sealed containment

A gasket seal around the lid opening provides containment integrity when closed. This seal prevents release of airborne contamination from stored materials and protects contents from environmental moisture. The sealed design supports regulatory compliance for radioactive material storage.

Decontamination-ready coating

The exterior features the same two-component polyurethane epoxy coating used across Nuclear Shields’ container range:

- Acid resistant — Withstands decontamination chemicals without degradation

- Shock resistant — Maintains coating integrity despite handling impacts

- Smooth finish — Non-porous surface prevents contamination adhesion and enables thorough cleaning

This specialized coating facilitates rapid decontamination and supports clean storage area maintenance.

Flexible handling

The decay cave includes multiple provisions for positioning and relocation:

- Forklift shafts — Integrated into the bottom frame for standard forklift handling

- Lifting hooks — Mounted on all four sides for crane operations with rigging straps or chains

These handling features enable initial placement in the decay storage area and subsequent relocation if facility layouts change.

Contact usProduct attachments

Login to see the attachments, otherwise contact us