Custom requests

Standard products don’t always fit your process. That’s why we offer fully customized shielding. Designed and built to match your specific technical, spatial, and operational requirements.

Our team can support you with:

Design and engineering based on your input or technical drawings

Material selection (lead, tungsten, stainless steel, PMMA, etc.)

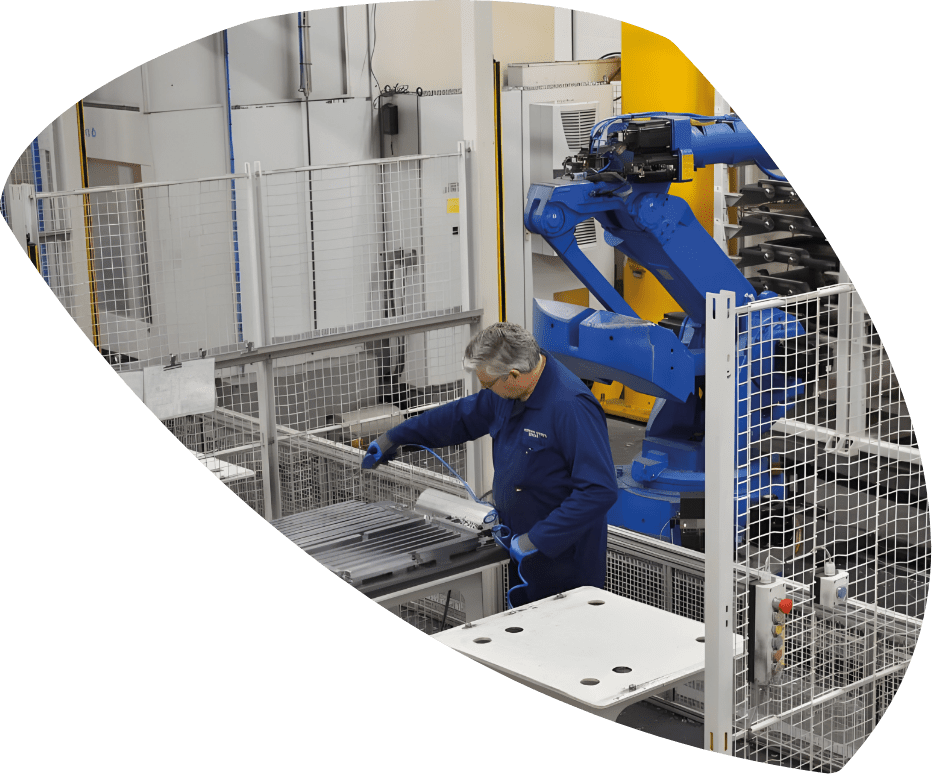

Custom machining, casting, and fabrication in-house

Integration of viewing windows, manipulators, electronics, or ventilation

Surface finish options for cleanroom or industrial use

We handle projects ranging from small one-offs to complete systems. Whether you’re working in healthcare, research, energy, or defense. We can help you build the shielding you need.

Send us your sketch, drawing, or idea, and our team will review the possibilities. We’ll give you a clear proposal with cost, lead time, and technical input.